Digital Solutions

SQ Guide System

SQ Guide System

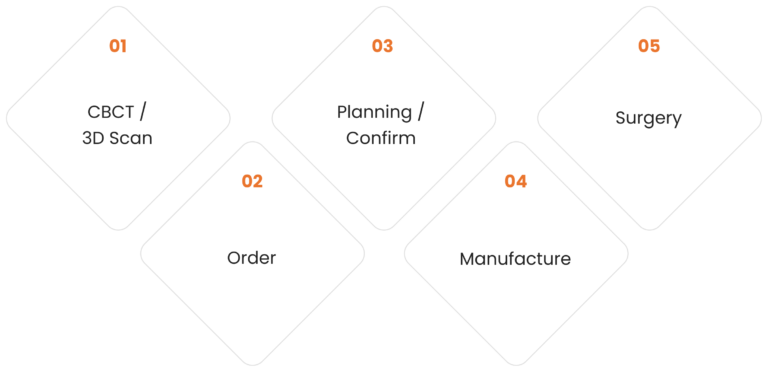

The SQ Guide is a Digital Implant Guide System Optimized for The SQ Implant Fixture

Full Solution Guide System

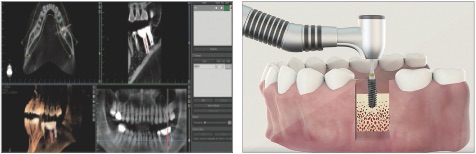

- Place the implant in the correct position by virtually doing the implant placement through the software

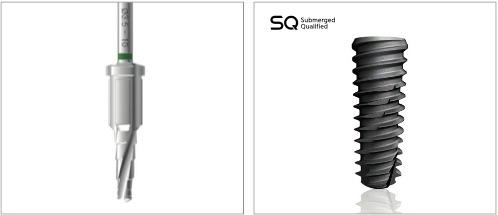

Exclusive Guide System for The SQ Implant

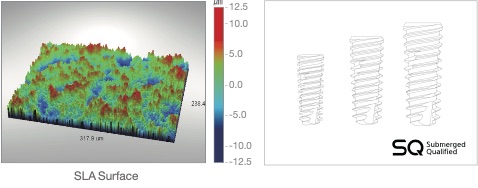

- Computer guided implant placement for the SQ Implant that has the advanced SLA surface

- The SQ Implant Fixture Sizes

- Diameter: Ø3.5, Ø4.0, Ø4.5, Ø5.0

- Length: 7.0mm, 8.0mm, 10.0mm, 12.0mm, 14.0mm

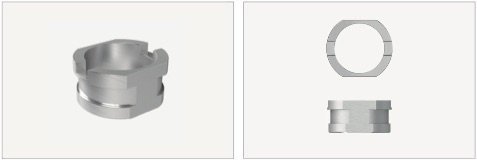

SQ GUIDE Sleeve

- Titanium metal sleeve is used

- SQ GUIDE Sleeve information

- Base Offset: 9.0mm

- Inner Diameter: Ø5.35

- Length: 3.5mm, 4.5mm

SQ GUIDE Software

- SQ GUIDE is available with Dentiq Guide S/W or Implant Studio S/W

- Chair-side production is possible with DENTIS Implant and sleeve library

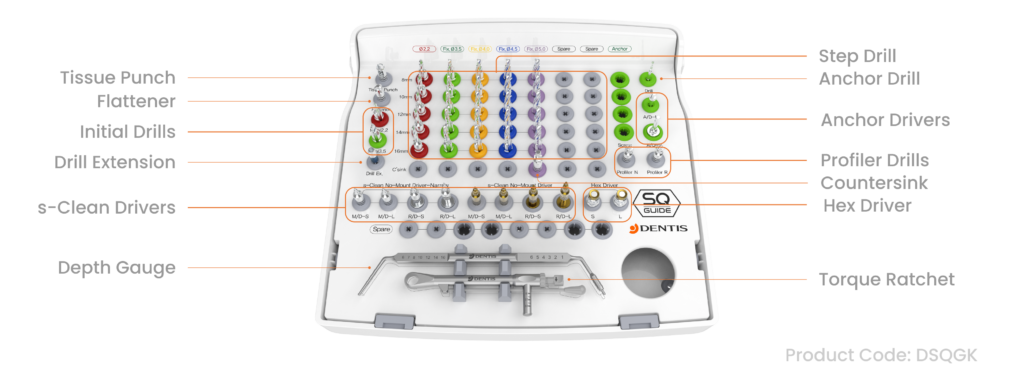

SQ Surgical Kit

Why SQ Guide Is Special?

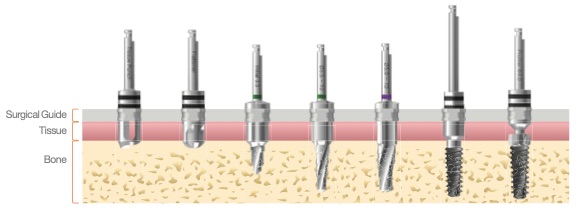

Safety

- Irrigation function added to prevent bone loss and bone heating

- Available exclusively for the Dentis SQ Implant

- Using a metal sleeve helps prevent contamination of the surgical site by guide resin, which may occur during drilling

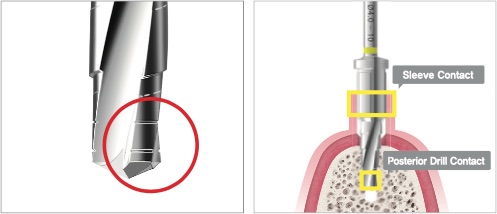

Accuracy

- With the initial drill (F Ø3.5 STEP Drill), you can drill without slipping because of the side cutting function

- Drilling can be performed with precision as the lower end of the trailing drill is anchored in the previously drilled site, while the upper end, or guide hole, is securely stabilized by the sleeve around the drill’s barrel

Convenience

- By adopting the multi-stage drill, the number of drills can be minimized and the operation can be performed quickly.

- Added convenience: Tissue Punch, Flattener, Profiler Drill, etc.

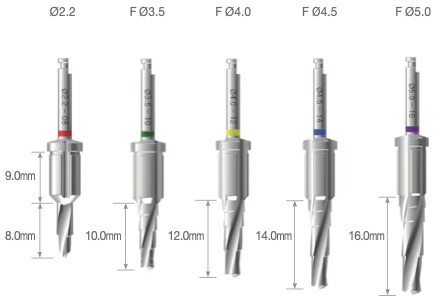

SQ GUIDE Kit Drill Specs

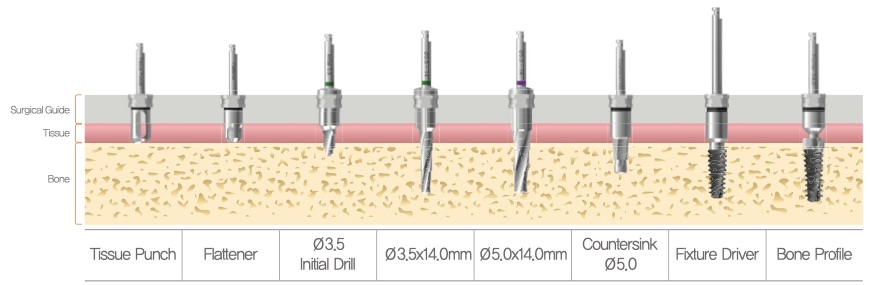

Countersink Drill

- Prevents excessive installation torque when widening cortical bone (especially when the offset is 13mm)

- Recommended RPM : 800 – 1,200

| Size | Product Code |

|---|---|

| Ø2.2 | DSQGID22 |

| Ø3.5 | DSQGID35 |

※ Irrigation function of drill part, prevention of bone heating

Initial Drill

- Used to form holes that ensure precise orientation at the initial stage

- Recommended RPM: 800~1,200

| Size | Product Code |

|---|---|

| Ø3.5 | DSQGCS35 |

| Ø4.0 | DSQGCS40 |

| Ø4.5 | DSQGCS45 |

| Ø5.0 | DSQGCS50 |

※ Additional purchase: Ø3.5, Ø4.0, Ø4.5

STEP Drill

- Used for establishing diameter and length for fixture placement

- Improved cutting ability and slip prevention through multistep structure and side cutting design

- Prevents bone heating with drill bit irrigation

- Recommended RPM: 800 – 1,200

| Length/Size | 2.2 | 3.5 | 4.0 | 4.5 | 5.0 |

|---|---|---|---|---|---|

| 8.0mm | DSQGSTD 2208 | DSQGSTD 3508 | DSQGSTD 4008 | DSQGSTD 4508 | DSQGSTD 5008 |

| 10.0mm | DSQGSTD 2210 | DSQGSTD 3510 | DSQGSTD 4010 | DSQGSTD 4510 | DSQGSTD 5010 |

| 12.0mm | DSQGSTD 2212 | DSQGSTD 3512 | DSQGSTD 4012 | DSQGSTD 4512 | DSQGSTD 5012 |

| 14.0mm | DSQGSTD 2214 | DSQGSTD 3514 | DSQGSTD 4014 | DSQGSTD 4514 | DSQGSTD 5014 |

| 16.0mm | DSQGSTD 2216 | DSQGSTD 3516 | DSQGSTD 4016 | DSQGSTD 4516 | DSQGSTD 5016 |

※ Irrigation function of drill part, prevention of bone heating

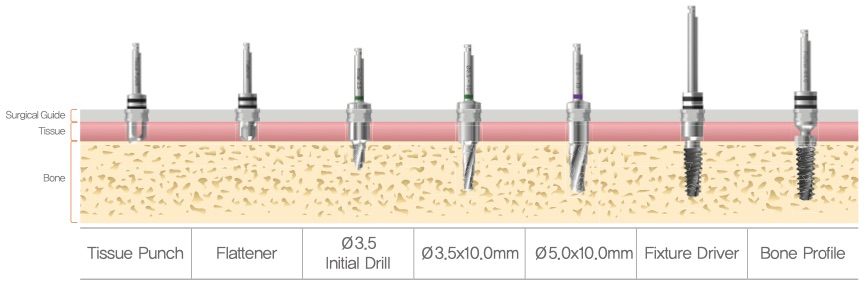

Drilling Protocol for Ø5.0x10.0mm Fixture(Offset 9.0mm)

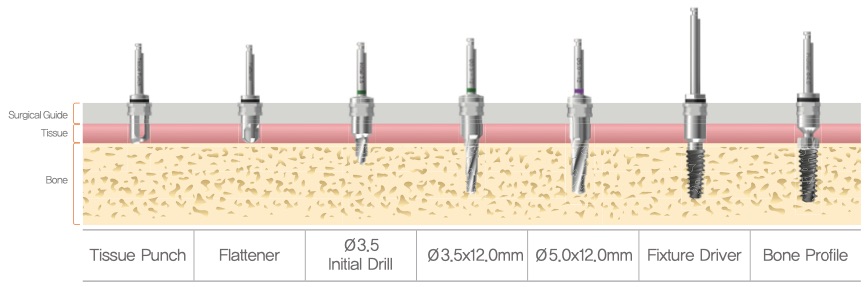

Drilling Protocol for Ø5.0x10.0mm Fixture(Offset 11.0mm)

Drilling Protocol for Ø5.0x10.0mm Fixture(Offset 13.0mm)

SQ GUIDE System Workflow